We were VERY impressed with the overall experience with these Rudd Rangers™! I would definitely do it again!

Over 11 weeks, they consumed about 8 50lb bags of feed (plus lots of grass and bugs. It is worth noting we raised them in the spring when conditions have been ideal. Temps rarely getting over 75 degrees and lots of new spring foliage growth). During their entire life, they probably drank around 180 gallons of water. We moved the tractor daily, and for the last 4 weeks we let them free range during the day. I would say these meat birds can be raised alongside laying hens (once they are old enough to not get picked on).

After losing 2 chicks within the first 48 hours, we had no other deaths or medical issues. ALL remaining 13 birds dressed out cleanly and healthy. Our birds were ordered as straight run (or a mix of male and female). We ended up with 4 roosters and 9 hens. The roosters were considerably larger, and we may order just roosters next time.

On processing day, the average live weight was 6 pounds, with the average weight of 4 pounds dead weight after gutting. There was no evidence of the health problems that plague typical Cornish Crosses, like wood breast or enlarged hearts.

This batch was the hardest emotionally for us to process. We had grown so fond of them and loved their friendly temperaments. At the end of the day though, we had to remember why we got them. The lived incredible lives! Felt the wind and sunshine on their feathers everyday, got to run free, and enjoyed a mixed diet. It is worth noting that after processing, their gizzards were FULL of flowers and grass. We cared for them to our utmost ability, and in return they have given us fresh, wholesome meat. A lot of people eat meat.

Without large chicken farms, we would not be able to eat as much chicken as we do. I am certainly not anti-chicken farm. Many of our friends and neighbors in our community raise chickens on an industrial scale.

However, we felt it the best decision for our family to raise our own birds from start to finish. More people like us can raise meat birds! It isn’t that hard, and doesn’t require huge amounts of space! Want to feel more connected to where your food comes from? Want to feel better about the quality of your food? Give your meat chickens a great life from start to finish, and you’ll never regret it!

The key to success on processing day is preparation.

Long in advance to the actual day, there are lots of things you need to have ready. Some items can be a one-time purchase, but will last you many batches of chickens. It really is only worth going through all this process if you are doing 10 or more birds.

We are by no means experts. Our setup has taken a few times to get totally streamlined. We still are improving and learned most of what we know from Youtube videos. Having everything laid out in “stations” and keeping supplies clean and sanitized is very important. The whole day can feel like a rush to get the birds cleaned and cool. We processed all 13 of ours in about 3.5 hours.

Here is a list of needed supplies:

- Access to power and water

- Kill Cone Station

- Propane Turkey Fryer

- De-Featherer Machine

- Large Sink or Ice Chests

- Processing Table

- Sharp filet knives and 1 cleaver

- Bagged Ice (7-8 Bags)

- Paper Towels, Clorox, Gloves, Sponges, Bleach, Soap

- Tupperware Containers

- Ziploc Freezer Bags

- Vacuum Sealer with Bags

Access to power and water

Some appliances will need power, and it is important to have a hose with running water available at all times. You will need to keep the temperature for the birds down as low as possible.

Kill Cone Station

You will need an area to do the actual dispatching. We like to do ours two chickens at a time. We use 2 small, plastic trash cans with holes drilled in the bottom. Gently and quietly hang the chicken upside down and ziptie its feet together. Lower it down into the cone and pull its head thorugh the hole. We dispatch them next by slicing either side of their necks and allowing them to bleed out for a couple minutes. This is by far the HARDEST part of processing them. It never really gets easy. It takes lots of praying and asking for forgiveness right before doing it. They will thrash around, and this can be very disturbing, but hopefully it is quick. They black out very quickly hanging upside down. (You need buckets underneath to catch blood).

Propane Turkey Fryer

After dispatching, we remove the head. It is best for your well-being to now start thinking of the chicken as one you’d buy from the store. Processing is not for the squeamish, but this part does get better with practice. We use a long wooden pole with a hook on the end to hoop the ziptied feet. We dunk the bird into hot water for about 8-10 seconds to scald the feathers. (Not too hot or long or you will cook the bird!)

De-featherer

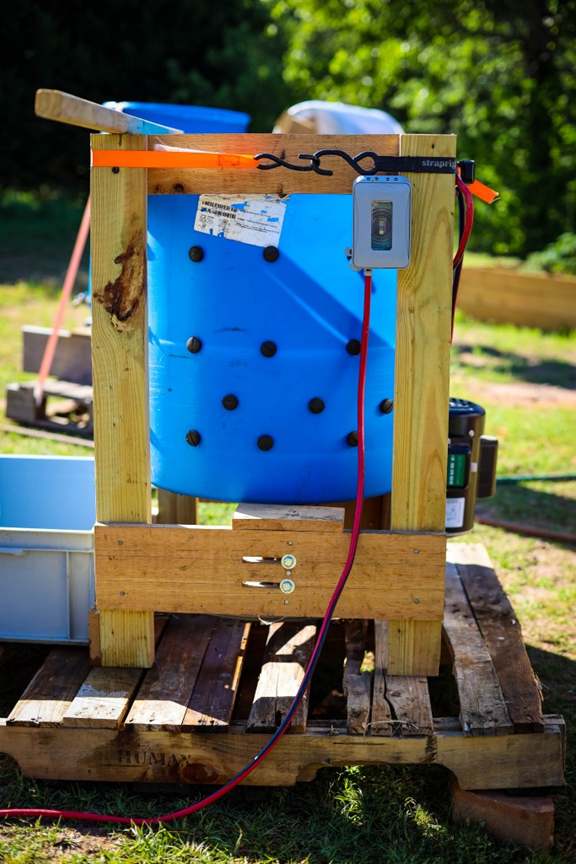

This is one piece of equipment you really should invest in making. My husband made ours using a washing machine motor and an old barrel. You drop the bird in, and flip the switch. It starts spinning and rubber nipples knock almost all the feathers off in about 25 seconds. (One person needs to be spraying the bird with cold water now to keep its body temperature down.) The feathers exit the machine through a large hole at the bottom and are collected in bucket. This piece is a lifesaver on time, and removes about 98% of all the feathers.

Large Sink or Ice Chests

After de-feathering, the carcass needs to be kept very COLD. We have a two bay stainless steel sink (found on Facebook Marketplace). We fill it with bags of ice and water to let all the birds sit. We like to dispatch all the birds first, doing 2 at a time, and gut/divide last.

Processing Table

Any clean table will do. We use a folding table. Here, have a large bucket on the ground to collect guts, and several tubberware containers with ice water on the table to divide up parts we want to keep. Some birds we keep whole, some we divide into breasts, legs, wings, thighs, livers, etc. I would strongly advise you to keep the carcasses, necks, wing tips, and feet. They can be used to make the best broth in the world later on!

Post-Processing

After bagging up the chicken, it is very, VERY important you let the meat “rest” in a fridge for 24-48 hours. After that, the best way to store the meat is to take it all out and vacuum seal everything as you’d like. I kept 6 birds whole heat shrink type bags. We also tried a meat grinder attachment for our stand mixer this time. Using thigh meat, we made some very nice ground chicken. All the bones and feet (minus toe tips) can be used to make the BEST, most healthy stock out there!

There’s lots of recipes and techniques online available for how to best use every part. All the innards, blood, and feathers are used to feed our catfish in the pond. In the end, nothing at all goes to waste!

Everything is finished up and done, and we will soon be ready to start our next batch of meat chickens! I absolutely can say I recommend the Rudd Rangers for an awesome, healthy, ideal backyard meat chicken! (or even just a friendly pet!)